Contact Us

Product

Linear motion

Transmission parts

Rotational motion

Positioning and fixing guide

Pneumatic components

Visit Factory

Corporate Introduction

Precision Manufacturing

Intelligent Warehouse

Product Research and Development

Staff Presence

Quick Links

About

News

Visit Factory

Contact Us

Follow us

Home Standard parts Spring·Gas Spring Bracket for Nitrogen Spring Installation For Head Installation Limited Type/For Head Installation Universal Type

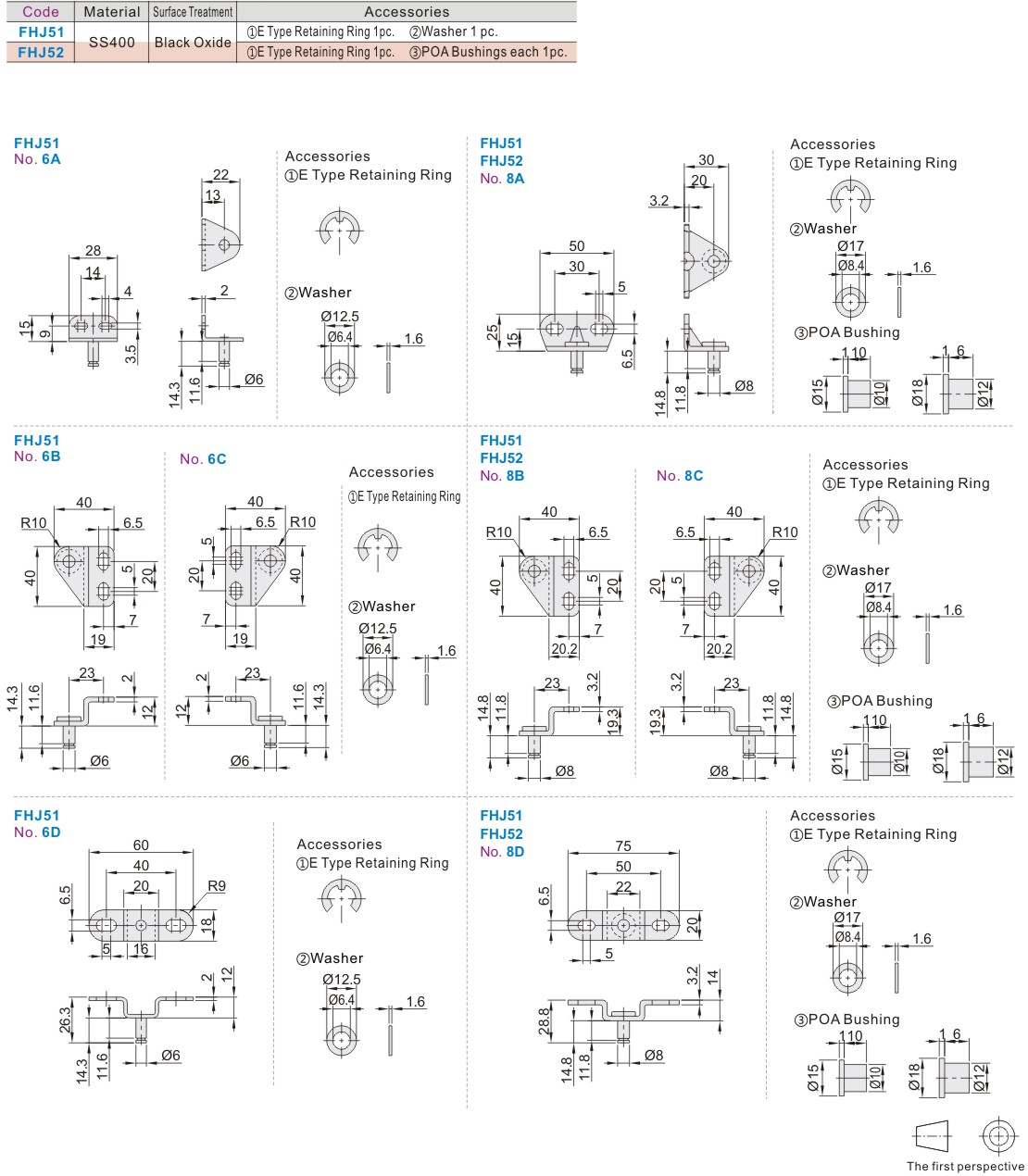

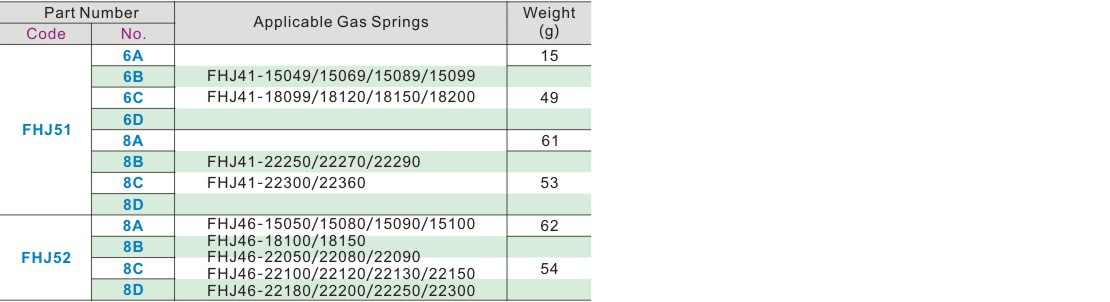

Bracket for Nitrogen Spring Installation For Head Installation Limited Type/For Head Installation Universal Type

Type: Nitrogen Gas Spring Installation Bracket

Origin: Domestic

Cost-Effectiveness: Standard Type

Type: Head Mounting Limiting Type/Head Mounting Universal Type

Material: SS400

Surface Treatment/Color: Black Chromate Gloss Treatment

Optional Accessories: E-Type Washer 1, Washer 1/E-Type Washer 1, POA Liner 1/E-Type Washer 1, Hinge Pin 1, POA Shaft Ring 2

Detail

Frequently asked questions about this product

1. Can rectangular springs be customized with stainless steel?

Rectangular springs cannot be customized with stainless steel. Although stainless steel has strong corrosion resistance, it has low tensile strength, so it cannot achieve the high load and good fatigue life of the original rectangular spring. At present, the rectangular springs produced by our company are made of 50CrvA alloy steel, which is not corrosion-resistant and rust-proof. The surface of standard products is painted, and products with unpainted and electroplated surfaces can also be customized according to the different needs of customers' special scenarios.

2. Can rectangular springs be stacked and used in combination?

There are two situations for analysis:

A. If the spring exceeds the height of the guide pin or countersunk hole when used in a stacked manner, it will cause the spring to bend and break.

B. If the height of the guide pin or countersunk hole is greater than the height of the spring, it can be stacked and used in combination, but please note (when the spring length becomes longer and the pitch remains unchanged, the corresponding spring constant will theoretically become half smaller).

3. Why do rectangular springs of the same model have color differences and different numbers of turns?

In order to meet the urgent needs of customers, our company has inventory for standard products. When the inventory quantity is lower than the safety warning line, it will be produced in advance accordingly. However, the color and number of turns of the springs may vary depending on the production batch, so there will be such differences in the same model of springs in stock, but this will not affect the load and life of the product. They are all in line with the standards and will not affect the use.

4. Are there parameters for the wire diameter of rectangular springs?

There are no parameters for the wire diameter of rectangular springs. The number of turns, pitch, and wire diameter of rectangular springs are not controlled (in order to ensure the load requirements, the number of turns and wire diameter and other parameters need to be adjusted for each batch, so there are differences in inventory), only the external dimensions and load of rectangular springs are controlled.

Recommending Commodities

Get In Touch

Copyright © 2010-2026 YIHEDA All Rights Reserved.