Aluminum profiles can be bent into various shapes such as C-shaped, U-shaped, S-shaped, elliptical, full circular, and curved shapes, based on customer preferences and customization requirements.

I. Process Overview

The aluminum profile bending process, also known as aluminum profile curving or bending, involves customizing and stretching aluminum alloy profiles using a bending machine to achieve a specific curvature. This process falls under the category of cold working, where the aluminum profiles are bent through cold-rolling to achieve the desired shape.

As the aluminum profile industry has evolved, the applications have become increasingly diverse, leading to a wide range of customer demands. The demand for aluminum profiles processed through bending has grown significantly due to their suitability for special equipment or industries.

II. Processing Principles

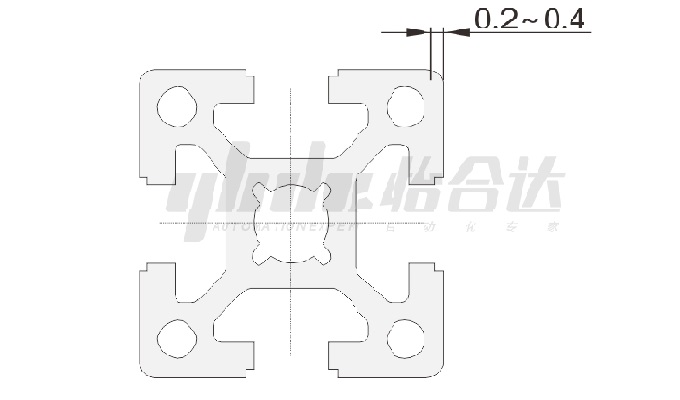

The process involves applying appropriate tension to the aluminum profile raw material based on its elasticity, yield strength, and elongation, while controlling the position of the material's neutral layer. The material is then stretched to the required curvature. It is crucial to ensure that the surface of the stretched aluminum profile remains smooth and even.

III. Features of Yiheda Aluminum Profiles

Yiheda aluminum profiles offer various features such as cuttability, the ability to tap threaded holes, drill through holes, create installation blind holes, countersink holes, sell as full bars, and assemble into frameworks. The cutting length ranges from 50 to 6000mm, with a cutting accuracy of ±0.5mm.

IV. Process Advantages

High Precision Processing:

Yiheda aluminum profiles employ advanced equipment and technology in the bending process, ensuring high-precision processing with a cutting accuracy controlled within ±0.5mm, meeting customer demands for dimensional accuracy.

Strong Flexibility:

Aluminum profile bending processes can be customized into various shapes, including C-shaped, U-shaped, S-shaped, elliptical, full circular, and curved shapes, according to specific customer requirements, enabling flexible applications in different scenarios.

Cuttability and Tapping Threaded Holes:

Yiheda aluminum profiles can be cut to a wide range of lengths and feature threaded hole processing, enhancing the functionality of the profiles, facilitating installation, and enabling versatile use.

Smooth Surface:

Strict control is maintained over the surface of the stretched aluminum profile raw material during the bending process, ensuring a smooth and even surface. This contributes to enhancing the aesthetic quality of the aluminum profiles, making them suitable for high-end equipment and decorative applications.

Sell as Full Bars, Assemble into Frameworks:

Yiheda aluminum profiles can be sold as full bars and, according to customer needs, assembled into larger structures such as frameworks, increasing their application flexibility and diversity.

Wide Range of Applications:

After undergoing the bending process, aluminum profiles exhibit enhanced applicability and can be widely used in special equipment, decorative architecture, mechanical manufacturing, and other fields, meeting the personalized requirements of different industries.

In summary, Yiheda aluminum profiles, through the bending process, satisfy the market demand for personalized, precise, and multifunctional aluminum profiles. The advantages of high-precision processing, strong flexibility, cuttability, and threaded hole tapping contribute to providing customers with high-quality customized services.