Aluminum has a relatively light weight, minimal springback during forming, high strength comparable to or exceeding high-quality steel, good plasticity, and is easier to control in complex shaping compared to stainless steel. It possesses excellent conductivity, thermal conductivity, and corrosion resistance. Currently, surface treatment processes for aluminum such as anodizing, drawing, and sandblasting are mature. Aluminum is widely used in mobile phones.

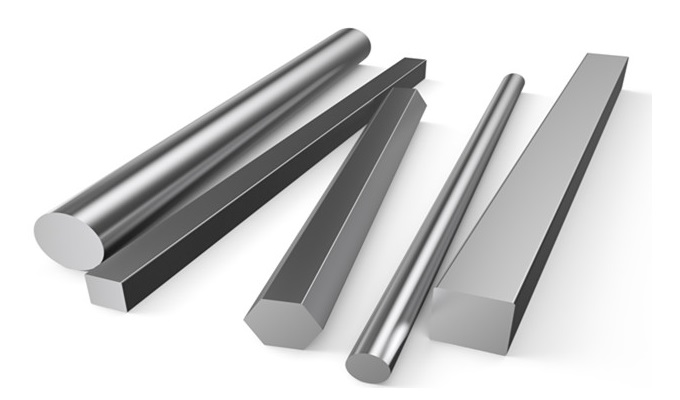

According to the processing method, aluminum alloys can be classified into deformed aluminum alloys and cast aluminum alloys. The alloy grades are mainly divided into 8 series.

Alloy Grade Representation

International Grade (represented by four Arabic numerals):

1XXX: Represents the pure aluminum series with a purity of over 99%, such as 1050 and 1100.

2XXX: Represents the aluminum-copper alloy series, such as 2014.

3XXX: Represents the aluminum-manganese alloy series, such as 3003.

4XXX: Represents the aluminum-silicon alloy series, such as 4032.

5XXX: Represents the aluminum-magnesium alloy series, such as 5052.

6XXX: Represents the aluminum-magnesium-silicon alloy series, such as 6061 and 6063.

7XXX: Represents the aluminum-zinc alloy series, such as 7001.

8XXX: Represents alloy systems other than the above.

Series One

The 1000 series has the highest aluminum content, with purity reaching over 99.00%. The last two digits of the grade determine the minimum aluminum content. For example, the 1050 series has a minimum aluminum content of 99.5% according to international grade naming principles. Series One aluminum has good formability and surface treatment properties, with the best corrosion resistance among aluminum alloys. It has lower strength, and higher purity corresponds to lower strength. Commonly used in mobile phones are 1050, 1070, 1080, 1085, and 1100 for simple extrusion forming. Among these, 1050 and 1100 can undergo chemical sanding, have a glossy surface, frosted effect, distinct material patterns, and good coloring effects. 1080 and 1085 mirror aluminum are used for bright lettering and frosted effects, with no obvious material patterns. Series One aluminum is relatively soft and mainly used for decorative or interior components.

Series Two

Known for higher hardness but poor corrosion resistance, the 2000 series includes aluminum-copper alloys with copper content ranging around 3-5%. These alloys, such as 2024, 2A16, and 2A02, are primarily used in aerospace applications and are not commonly used in conventional industry.

Series Three

The 3000 series, with manganese as the main component, includes alloys like 3003, 3105, and 3A21. With a manganese content between 1.0-1.5, this series provides good rust resistance. It is commonly used for liquid product tanks, containers, building processing parts, construction tools, various lighting components, and thin sheet processing of pressure vessels and pipelines. It exhibits good formability, weldability, and corrosion resistance.

Series Four

With silicon content usually between 4.5-6.0%, the 4000 series, represented by 4A01, consists of aluminum plates with relatively high silicon content. These alloys are suitable for construction materials, mechanical parts, forging materials, welding materials, with good fluidity, minimal solidification shrinkage, low melting point, good corrosion resistance, and heat and wear resistance.

Series Five

The 5000 series, with magnesium as the main element, includes alloys like 5052, 5005, 5083, and 5A05. Also known as aluminum-magnesium alloys, they have low density, high tensile strength, and high elongation. Among them, 5052 is commonly used in mobile phones for its moderate strength, good corrosion resistance, weldability, and formability. However, its coloring effect is not ideal, making it suitable for sandblasting but not for chemical sanding or frosted finishes.

Series Six

The 6000 series aluminum alloy, represented by 6061, contains magnesium and silicon. It combines the advantages of the 4000 series and 5000 series. 6061 is a cold-processed aluminum forging product suitable for applications requiring high corrosion and oxidation resistance. It has good usability, is easy to coat, and has good processing properties. Commonly used in mobile phones are 6061 and 6063, with 6061 having higher strength than 6063. These alloys are used for casting, allowing the production of intricate structures like snap-fit components.

Series Seven

The 7000 series, containing zinc as a major element, includes aluminum alloy 7075. Also belonging to the aerospace series, it is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy, and a super-hard aluminum alloy with good wear resistance. Currently, it relies on imports, and the production process in China needs improvement.

Series Eight

The 8000 series aluminum alloy, with 8011 being a commonly used representative, belongs to other series. It is mostly applied in aluminum foil production and is not frequently used for aluminum rod production.

This classification and explanation provide an overview of the characteristics and applications of different aluminum alloy series, especially in the context of their use in mobile phones.