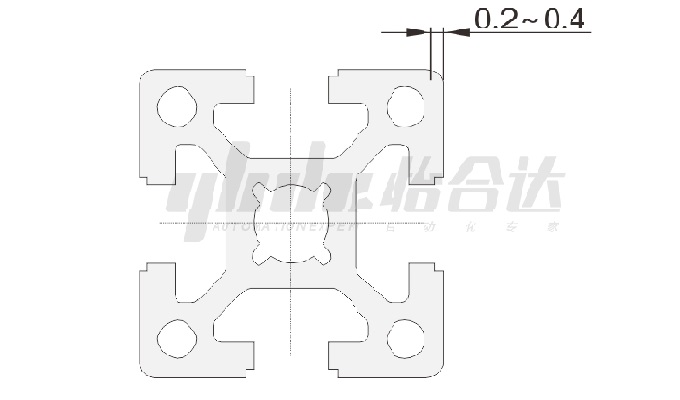

Industrial aluminum extrusion, as one of the most common raw materials in the field of industrial automation, have an extensive range of applications. Additionally, various products made from aluminum extrusions have become indispensable across different industries. The following paragraphs will provide a brief introduction to several common application examples of industrial aluminum extrusions, aiming to inspire readers who are new to the world of aluminum profiles.

1、Aluminum Extursion Frames

Aluminum extrusion frames play an important role in supporting large-scale automation equipment or instruments. By customizing aluminum profile frames or brackets and adding corresponding wheels or casters, it becomes possible to achieve free movement of bulky automation equipment. A representative example is the material used for conveyor line frames, which is aluminum profile. The overall installation and disassembly process is simple and convenient.

2、Machine Guarding Systems

Machine guarding systems are primarily used to provide fine segmentation of work areas, with the aim of protecting both production equipment and operators. Aluminum extrusions are used for connecting various small machine guarding panels together.

3、Equipment Enclosures

Equipment enclosures, such as protective covers, are not necessary for all machinery. These enclosures are designed to protect fragile components and prevent the escape of debris during operation. Applying protective covers to equipment not only enhances the overall aesthetics but, more importantly, increases the safety factor.

4、Industrial Ladders

Industrial ladders are manufactured using aluminum profiles of various models. The surface of the aluminum profiles used for industrial ladders is typically treated with sandblasting and oxidation or alkali sanding and oxidation. These treatments increase the surface friction coefficient and remove any small burrs or protrusions.

5、Workstations

Workstations are among the most common applications of aluminum extrusions, widely used across various industries. Different types of workstations are suitable for different work scenarios. For example, conveyor workstations are commonly used in assembly lines, anti-static workstations are suitable for lithium battery and semiconductor factories that require high anti-static performance, and flow rack workstations are mainly used in conjunction with automatic sorting equipment.

6、CleanBooth

CleanBooth require aluminum extrusions that have undergone anodization surface treatment. This treatment enhances the aluminum profiles' anti-static capabilities and ensures a clean surface that is not prone to dust accumulation, making cleaning extremely convenient.

7、Automotive Fixtures

The application of aluminum extrusions in the automotive industry is growing rapidly. Currently, aluminum extrusions are used as raw materials for automotive support structures, display stands, seat frames, testing racks, and other components across most automotive brands. In the future, the utilization of aluminum profiles in the automotive industry is expected to continue to rise.

Apart from the typical industries and examples mentioned above, industrial aluminum extrusions have numerous untapped potential applications. It is believed that in the near future, the use of aluminum profiles will continue to expand into high-end and precision fields while maintaining steady development and widespread adoption.