Introduction

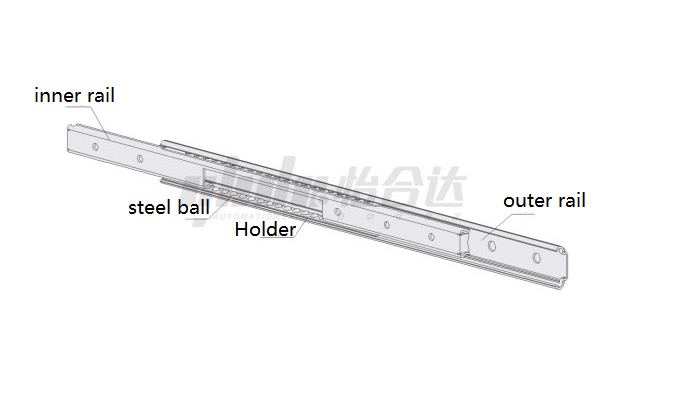

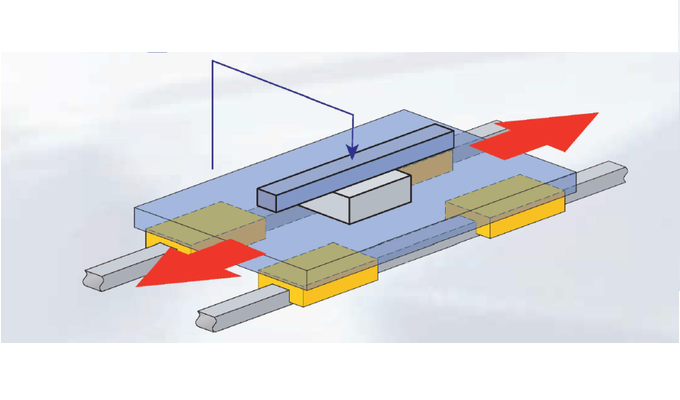

Linear rail is a common and crucial component in modern industries, enabling precise linear motion. It plays a significant role in various sectors, including mechanical manufacturing, automation, robotics, and medical equipment. However, understanding its working principles, applications, and common questions can be challenging for those new to linear rail. In this article, we aim to address some frequently asked questions about linear rail, helping you better understand its importance and applications. Whether you're an engineer, manufacturer, or interested in linear rail technology, we hope this article provides valuable information and insights. Let's delve into the world of linear rail together!

1、What is the highest temperature that linear rails can withstand?

In general, linear rails can handle temperatures of up to 80°C. However, certain models made from high-temperature resistant materials can withstand temperatures up to 150°C.

2、What is the maximum speed achievable with linear rails?

Linear rails manufactured in Taiwan and mainland China typically reach speeds of up to 1.2 meters per second. Some international brands can achieve speeds of up to 3 meters per second.

3、How long can linear rails be?

Typically, the full length of linear rails is up to 4 meters, with select models capable of reaching 6 meters. Micro linear rails have lengths ranging from 700mm to 2000mm.

4、What is the hardness and material used for linear rails?

Linear rails are typically carbon steel with a surface hardness ranging from 58° to 62°.

5、What are the minimum and maximum specifications for linear rails?

Linear rails can be manufactured with a minimum specification of 3mm and a maximum specification of up to 120mm.

6、How often should linear rails be maintained?

Regular maintenance is recommended after every 100 kilometers of operation for linear rails operating under unloaded conditions.

7、In which direction should lubrication grease fittings be installed on linear sliders?

Unless specified otherwise, lubrication grease fittings should generally be installed with the lubrication holes facing the opposite side of the reference surface.

8、What is the recommended amount of grease for linear rails?

In general, it is advisable to apply grease that fills approximately 30% to 60% of the slider's internal space.

9、Can linear rails be used underwater?

Ordinary linear rails are typically not suitable for underwater use. If underwater usage is required, selecting a series with high corrosion resistance is necessary.

10、What is the maximum working temperature for bellows-type dust covers?

Standard dust covers can withstand temperatures up to 80°C. If the dust cover base is made of fiberglass, it can withstand temperatures up to 300°C. Dust covers with an intermediate plate made of polytetrafluoroethylene (PTFE) can withstand high temperatures ranging from 250°C to 300°C.

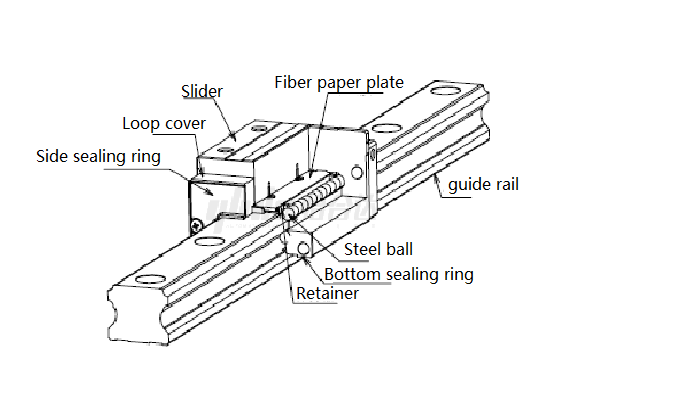

11、Do sealing gaskets need to be removed using linear rails in a cleanroom?

Sealing gaskets effectively prevent grease leakage in non-highly clean environments (without settling airflow). However, in highly clean settings, it is advisable to remove the sealing gaskets as they can generate friction and contribute to dust formation.

12、What should be considered when using a grease gun to lubricate linear rails?

When applying grease to the slider, it is recommended to do so in multiple stages. After each application, slide the slider approximately five times its length and repeat it several times.

Injecting all the grease at once may cause some leakage through the seals, leading to inadequate grease being applied to the slider.

After successfully applying the specified grease, ensure its uniform distribution throughout the slider by sliding it approximately five times its length and repeating this process multiple times.

If the rail length is less than five times the slider length, slide the slider to the maximum stroke length whenever possible.

Adjust the number of applications based on the grease gun specifications and the amount of grease.

13、What issues can arise if the slider disengages from the rail?

The steel balls will remain in place for products with ball retainers even if the slider disengages. However, there are two possibilities for other types: those with ball retention and those without. In cases without ball retention, the steel balls may disengage when the slider comes off. This can be addressed by using dummy rails and plugs.

14、Why does the slider develop groove peeling after some use?

The peeling of grooves and the subsequent damage to steel balls can be attributed to the shedding of iron chips, indicating the end of the ball's lifespan. This situation can occur due to excessive loading, incorrect installation, or uneven force distribution.

15、 I noticed indentations on the rail and fractured steel balls after using it. What could be the reason behind this?

The main reason for this issue is overloading, causing the steel balls to disengage from the rail and subsequently fracture, leading to continuous damage.

16、 Why do the end caps and end seals of the slider deform or fracture after a period of travel?

The incorrect installation method can result in uneven force distribution between the slider and the rail, leading to deformations or fractures of the end caps and end seals. It can also be caused by external forces impacting the components.

17、Why am I unable to securely fasten the slider in place?

Poor locking methods or improper application of force can prevent the screws from being tightened properly, resulting in damaged threads and difficulties in securing the slider.

18、Why is there a height difference and step-like effect when joining the linear rails?

It is likely due to inadequate cleanliness. Previously, there may have been instances where the BA sections were connected, resulting in a slight unevenness when touched with fingers. This can cause uneven movement of the slider and reduce its lifespan.

19、What is the recommended usage for cleanroom or food industry environments?

For cleanroom or food industry environments, it is recommended to use special lubricants or oils as specified by the customer.

20、 Are there stainless steel options available for linear rails?

Currently, stainless steel options are available only for miniature series products, while the standard series does not have stainless steel options. Choosing a chrome-plated surface treatment is suggested, which can meet certain requirements.

21、 Can stainless steel balls be used instead of steel balls?

Steel balls used in linear rails are generally made of high-carbon chromium-bearing steel.

Conclusion

This article addresses some common questions about linear rails, hoping to provide helpful insights. As an essential component in modern industry, linear rails offer precise and stable linear motion solutions for various applications.

When using linear rails, following the manufacturer's recommendations and guidelines and choosing the appropriate model and specifications that suit your application needs is important. Regular maintenance and upkeep are also crucial to ensure the normal operation and longevity of the linear rails.

If you encounter any issues while using linear rails or require more in-depth technical guidance and support, consulting relevant professionals or contacting the manufacturers is recommended.

The development and application of linear rails are continuously evolving, and with advancing technology, we can expect more innovations and improvements. By staying updated with the latest trends and continuously learning about the advancements, you can fully leverage the potential of linear rails, bringing higher efficiency and quality to your projects.

We hope this article has deepened your understanding of linear rails and provided practical assistance in your work and projects. If you have any further questions or inquiries regarding linear rails, please feel free to comment or contact us. Thank you for reading, and we wish you success in applying linear rails!