The straightness of linear guide rail as we know, a linear guide ral is a component that guides a device (or slider) to move in a straight line in a predetermined direction. Straightness is a form tolerance that limits the variation of the actual line relative to the ideal line. So, what is "straightness of linear guides"? This is a precision index that users often mention but cannot find any explanation for in the manufacturer's catalog.

In fact, the "Straightness of linear guides" is a very general concept, generally including two aspects: free straightness of the slider and straightness of the guide's movement. Let's discuss these in detail.

1. What is the free straightness of the slider?

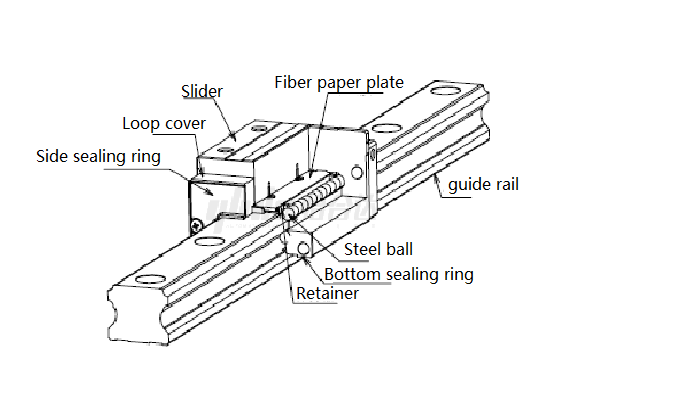

The free straightness of the slider refers to the straightness of the reference plane of the slider in its free state before installation. During the manufacturing process, machining stress can cause the slider to warp (see Figure 1). In addition, handling and storage processes also have some impact on the straightness of the slider in its free state. Therefore, the amount of warping can vary.

2. What is the straightness of the slider in its free state?

IKO does not specify the straightness of the standard product in the free state of the slider. When there are requirements for the free straightness of the slider (such as in cases where the rigidity of the installation surface is weaker than that of the guide), special drawings need to be provided. In general, even if the straightness is poor, a larger curved profile would be better, as it can be straightened during installation. It should be noted that extreme control of the free straightness of the slider would lead to many small bends after the correction process, making it difficult to achieve good straightness during installation.

3. What is the straightness of the guide's movement?

The straightness of the guide's movement refers to the straightness of the trajectory of the slider on the guide after installation. Before installation, the straightness of the guide's movement is approximately the same as the free straightness of the slider. After installation, the actual movement straightness can be greatly improved. This is because during the grinding process of the track groove, the slider is fixed on a very precise mounting surface for processing. Even if the free straightness of the slider is poor after removal, the dimensional accuracy between the reference surface and the track groove is guaranteed. Therefore, as long as the slider is fixed with screws at the specified torque on a surface with good precision, a very good straightness can still be achieved.

4. What factors affect the straightness of the linear guide's movement?

The main factors are as follows:

① The installation straightness of the slider.

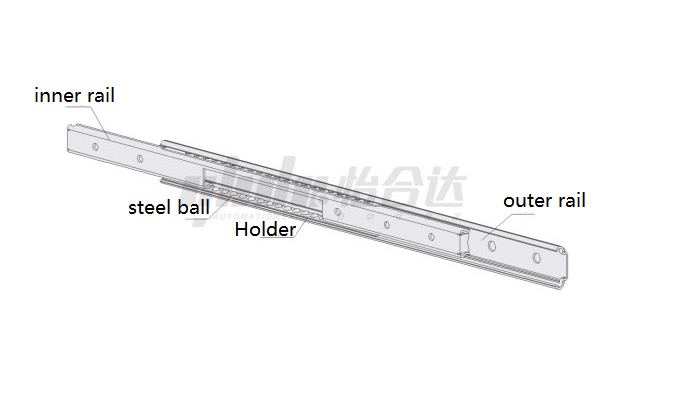

② The roundness (cylindricity) of the steel balls (cylindrical rollers) and the mutual differences between each rolling element.

5. What is the parallelism of the guide's movement?

For the definition and measurement method of the parallelism of the guide's movement, please refer to the article: "IKO Linear Guide Precision Specifications". The reason for mentioning this is that many customers often confuse the parallelism of the guide's movement with the straightness of the guide's movement. It should be emphasized that these are two different concepts. The former has specified values by the manufacturer, basically determined by the processing, and its measurement value must have a relative reference and belongs to positional tolerance; the latter has no specified values by the manufacturer, mainly determined by the installation, and its measurement value does not require a relative reference, belonging to form tolerance. To give an analogy, a railway has two rails, and the rail at the curve is bent. We can say that the straightness of this rail is not good, but the parallelism of the left rail to the right rail is good.

6. What is the straightness of the slider's movement?

The straightness of the slider's movement refers to the degree to which the movement trajectory of the slider deviates from the ideal straight line (see Figure 2). When the slider is mounted on a single guide rail, the straightness of the slider's movement is equivalent to the straightness of the single guide rail. When the slider is mounted on two or more guide rails, the straightness of the slider's movement is generally better than that of a single guide rail due to the averaging effect.

Figure 2 Definition of straightness of movement

Refers to the degree to which the movement of the slide that should be a straight line deviates from an ideal straight line.

Horizontal straightness: the movement of the slide in the left and right (horizontal) directions of the moving axis.

Vertical straightness: the movement of the slide table in the up and down (vertical) direction of the moving axis.

Measurements are made with measuring rods and indicators or laser straightness measuring systems. to make each other equal

The minimum distance between two straight lines of a row to represent a measurement.

7. How to improve the straightness of the slider's movement?

Methods to improve the straightness of the slider's movement:

① Improve the mechanical processing accuracy of the mounting surface (straightness of the slider mounting surface). It is effective for parts machined by cutting but has little effect on parts machined by grinding. *For reference: In the case of two guide rails and four sliders, if assembled into a slider, the movement accuracy will be improved to about one-third of the mounting surface accuracy (when the slider stroke is relatively short compared to the base length).

② Improve the installation accuracy of the guide rail. Do not rely solely on pressing against the reference surface for assembly, use a straight edge to improve the installation straightness. *In the horizontal direction, the slider can be corrected while installing, but in the vertical direction, it cannot, so improving the accuracy in the vertical direction will be relatively difficult.

③ Change the ball-type linear guide to a cylindrical roller-type linear guide. Optimal roller cycle design and more rolling elements can suppress small fluctuations.

8. What kind of guide rail installation structure can better ensure the straightness of the slider's movement?

For applications requiring precision and rigidity in linear motion, set two base mounting surfaces and one working table mounting surface (see Figure 3). This makes it easier to adjust the horizontal straightness during installation, and the movement accuracy is easier to maintain when subjected to lateral dynamic loads.

Figure 3 Installation example

9. What kind of guide rail specifications can improve the straightness of the slider's movement?

Regardless of how good the machining accuracy of the slider mounting surface is, when the rail is fixed with screws, the rail groove will undergo slight deformation, thus affecting the straightness of the slider's movement. At this time, if the standard pitch of the linear guide is changed to a half-pitch specification (/HP), the straightness of the movement can be greatly improved.