Contact Us

Product

Linear motion

Transmission parts

Rotational motion

Positioning and fixing guide

Pneumatic components

Visit Factory

Corporate Introduction

Precision Manufacturing

Intelligent Warehouse

Product Research and Development

Staff Presence

Quick Links

About

News

Visit Factory

Contact Us

Follow us

Home Standard parts Spring·Gas Spring Compression Spring Outer Diameter Reference Stainless Steel Allowable Displacement L × (27~40)%

Compression Spring Outer Diameter Reference Stainless Steel Allowable Displacement L × (27~40)%

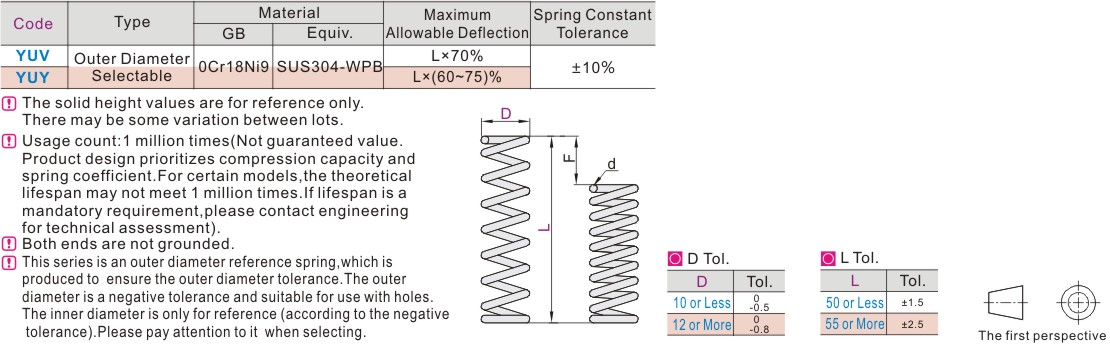

Type: Compression Spring

Maximum Compression Length: L70%/L60~75%

Reference Hole: Outer Diameter Reference Type

Type: Fixed Length

Material: SUS304-WPB

Surface Treatment/Color: None

Detail

![]()

![]()

Frequently asked questions about this product

1. Are there any requirements for the assembly between the inner diameter of the spring and the guide shaft?

A. The gap between the inner diameter of the spring and the guide pin: When the gap between the inner diameter of the spring and the guide pin is too small, it will cause the spring to wear and break. On the contrary, if the gap is too large, it will cause the spring to twist and break. The best gap is about -1mm of the inner diameter of the spring.

B. The outer diameter of the spring and the countersunk hole: If the gap between the countersunk hole and the spring is too small, the compression of the spring will cause the outer side to expand and rub against the countersunk hole, causing concentrated force to break. The best countersunk hole diameter is about outer diameter + 1.5mm.

2. Why can 304 stainless steel springs also be attracted by magnets?

Due to the wire processing technology (drawing process), the wire itself has some weak magnetism (can be adsorbed on the magnet). In addition, the processing technology during the production of the spring (cold processing produces large bending deformation) will also make the product weakly magnetic, and the magnetism is not easy to eliminate, so 304 stainless steel springs are also magnetic.

3. What is the difference between the clamping length and Fmax of the compression spring? Why does the clamping length + Fmax ≠ total length?

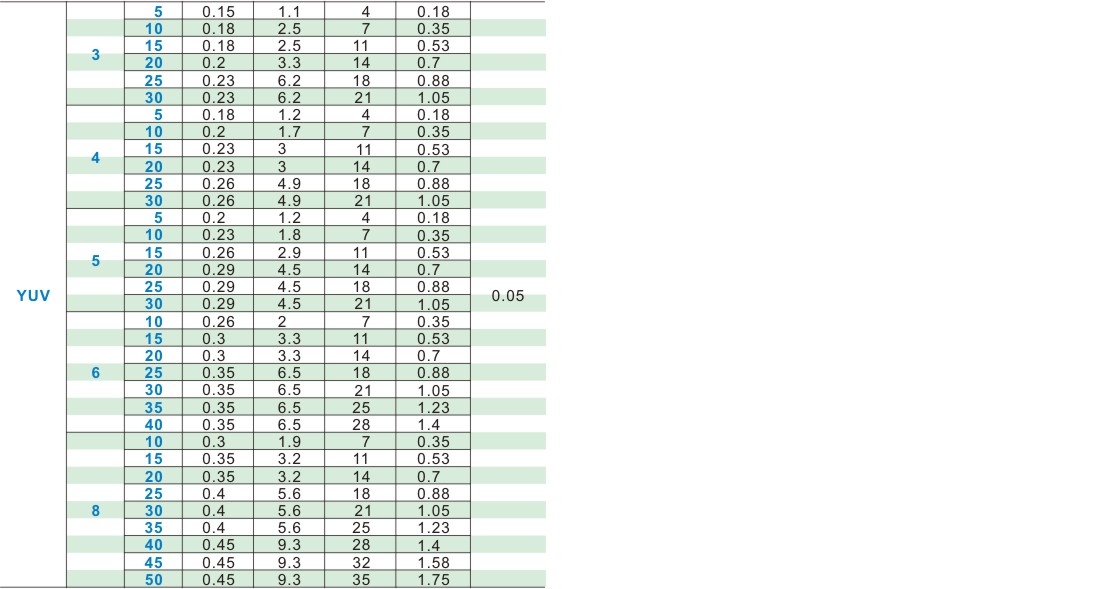

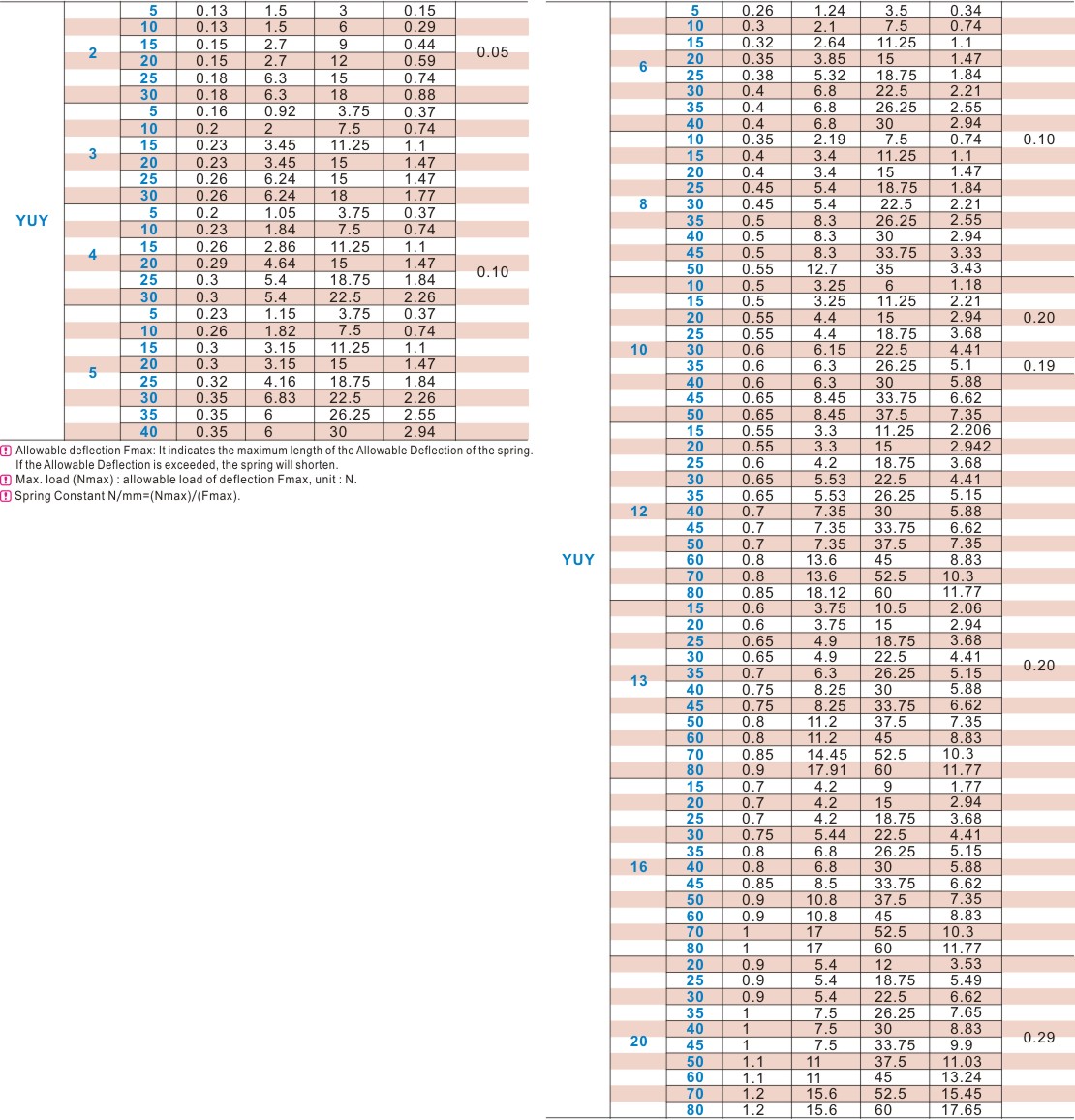

A. The clamping length refers to the total length of the compression spring after it is compressed and coiled. It is generally a theoretical value and is for reference only. Fmax is the maximum compression amount, which refers to the maximum compression amount of the spring while ensuring the theoretical life. It is generally not recommended to use it beyond this stroke.

B. Since the spring is not fully compressed at the maximum displacement, the total length L-Fmax is greater than the clamping length.

4. How to calculate the number of turns of the compression spring?

Regarding the total number of turns of standard products, the simplest way is total number of turns = clamping length/wire diameter, but please note that the total number of turns calculated theoretically can only be used for reference.

5. For the length-specified compression spring, what do the types A and B mean? For example, what is the difference between YFUR-D20-L50-A and YFUR-D20-L50-B?

- The biggest difference between types A and B in this series is the load difference. The spring load of type A is smaller than that of type B.

- For example, YFUR-D20-L50-A and YFUR-D20-L50-B have the same dimensions, but due to the difference in pitch, the load is also different.

Recommending Commodities

Get In Touch

Copyright © 2010-2026 YIHEDA All Rights Reserved.