Contact Us

Product

Linear motion

Transmission parts

Rotational motion

Positioning and fixing guide

Pneumatic components

Visit Factory

Corporate Introduction

Precision Manufacturing

Intelligent Warehouse

Product Research and Development

Staff Presence

Quick Links

About

News

Visit Factory

Contact Us

Follow us

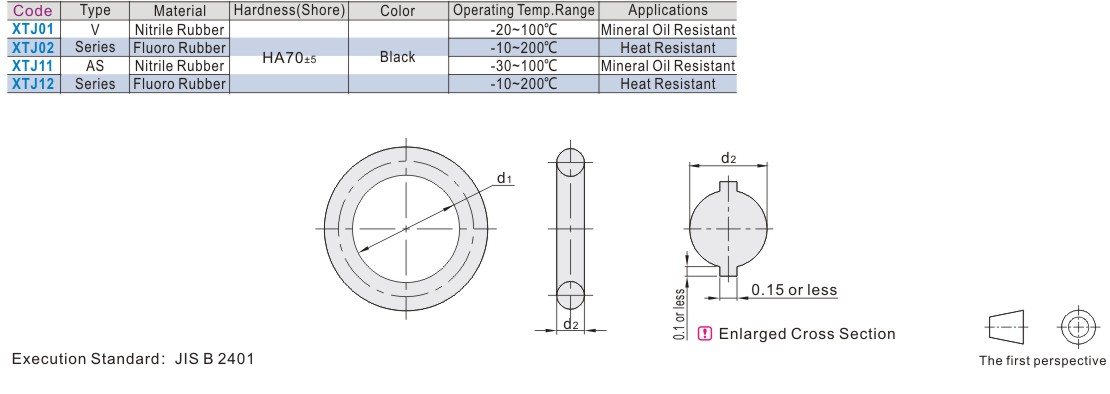

O-Ring V Series /As Series

Type: O-Ring

Series: V Series/AS Series

Cost-Effectiveness: Standard Type

Material: Nitrile Rubber/Fluororubber

Hardness (Shore): HS65

Use: Resistant to Mineral Oil/High Temperature

Detail

Video

![]()

Frequently asked questions about this product

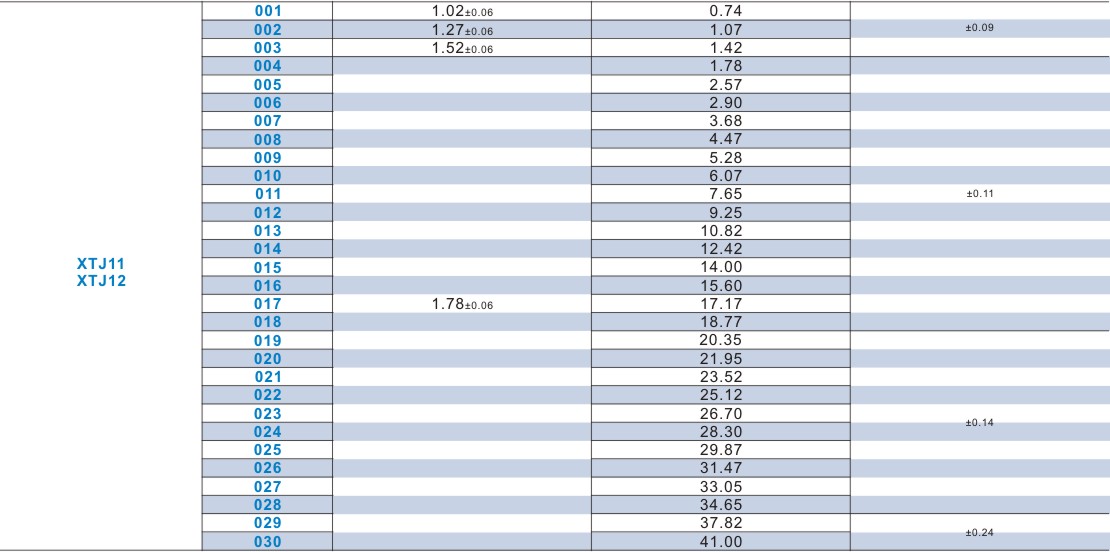

1. How to choose an O-ring?

Confirm the wire diameter, inner diameter, material and hardness of the O-ring, and consider the working conditions. For example, if you need resistance to mineral oil, choose nitrile rubber. If you need resistance to high temperature, choose silicone rubber. If you need resistance to wear and pressure, choose fluororubber or perfluororubber or choose according to industry characteristics, such as the semiconductor industry recommends non-fading black fluororubber, etc.

2. What should I do if I can't find the required size?

① If our standard parts do not meet the requirements, you can choose a similar size. For the same wire diameter, you can choose a smaller inner diameter; for the same inner diameter, you can choose a larger/smaller wire diameter;

② The range of selection can be determined according to the size. For small-sized wire diameters, you can choose ±0.05~0.1, and the inner diameter can choose ±0.5~1. For large-sized (inner diameter 300 and above), you can choose ±0.5, and the inner diameter ±3~5. You can also contact our technical staff for recommendations.

③ Our company accepts customization and can provide dimensions or drawings for customization. The specific price is to be determined.

3. Why is the price sometimes higher when customizing O-rings?

The price of customized products is related to quantity, size, and material. If the quantity is small or the material is perfluororubber, the price will be higher.

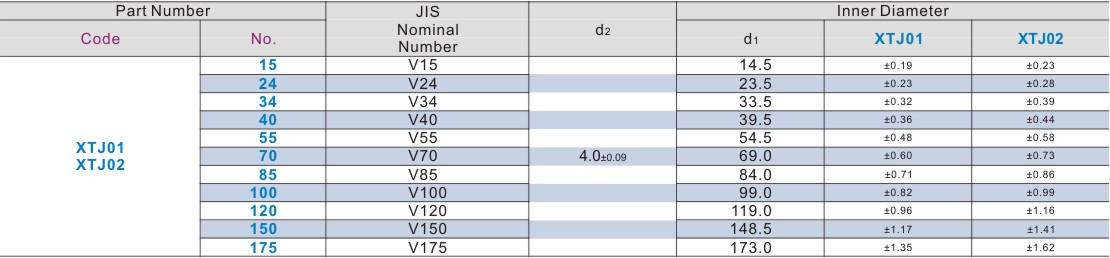

4. What is the difference between different series of different models?

The differences between the series of O-rings are:

1) Different specifications

2) Different standards of use:

① Japanese standard: P series, S series, G series, V series

② American standard: AS series

③ National standard: National standard series

3) Different uses:

① P series, AS series, National standard series are for fixed use and sports use

② S series and G series are for fixed use

③ V series is for vacuum use

Get In Touch

Copyright © 2010-2026 YIHEDA All Rights Reserved.