From the classification point of view, both the lead screw module and the timing belt module belong to the linear module, and the linear module is widely used in a variety of automation equipment such as grabbing, handling, transferring, packaging, dispensing, cutting, etc. So what are the specific differences between the lead screw module and the timing belt module?

1. Structural Composition

The composition structure of the lead screw module and the timing belt module is relatively complex, but the specific components of the two types of products are still quite different.

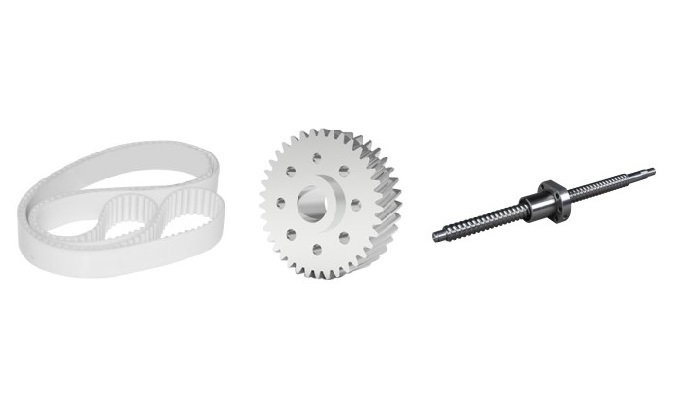

The main components of the lead screw module include the base, slide, cover, guide rail, fixed seat, support seat, ball screw, bearing, coupling, motor, photoelectric switch, etc. The main components of the timing belt module include the base, slide, cover, guide rail, active seat, driven seat, timing belt, timing wheel, motor, photoelectric switch. The structural composition of the screw module includes a ball screw, which is also the biggest difference between it and the timing belt module.

2. Functional Characteristics

Under working conditions, the maximum speed of the screw module can reach 1.5m/s, and its load level is about 150kg. In terms of accuracy, the repeatability of the screw module is ±0.01mm. Its maximum effective stroke is about 1.5m.

The maximum speed of the timing belt module is 2~3m/s, and the load level is slightly lower than that of the screw module, which can reach 85kg. The repeatability of the timing belt module is ±0.04mm, which is slightly worse than that of the screw module. However, the effective stroke of the timing belt module is much larger than that of the screw module, which can basically reach about 4m.

3. Related Knowledge

1) What precautions or restrictions are determined by the structural characteristics of the screw module and the timing belt module?

①The transmission backlash of the ball screw, one of the components of the screw module, is very small and has a critical speed limit, but its positioning accuracy is very high.

②The noise of timing belt transmission is low and there is basically no critical speed limit. It is more suitable for long-stroke high-speed movement, but the meshing transmission method still has a certain backlash, so its positioning accuracy is slightly lower than that of the screw module.

2) Based on the characteristics of the screw module and the timing belt module, how should the corresponding module be selected?

①If the working condition has a short stroke, the speed requirement is low but the accuracy requirement is high, in this case, the screw module can be selected.

②If the working condition has a long stroke, the speed requirement is high but the accuracy requirement is not high, then the timing belt module will be a more reasonable choice.

3) Why is the Z axis usually not using the timing belt module?

①The reason why the Z axis usually does not use the timing belt module is that the maintenance and maintenance frequency of the timing belt module is relatively high. This is because the timing belt is affected by tension for a long time and is prone to deformation, which will affect the positioning accuracy over time. Therefore, it is necessary to adjust the tension of the timing belt regularly.

②When the timing belt reaches its service life, it is easy to break and other problems. Breaking will cause the end of the Z axis to fall freely, posing safety hazards such as injury or damage to the machine.