Introduction

Timing belts and timing pulleys are important components in a wide range of machinery, from automotive engines to industrial manufacturing equipment. These belts and pulleys work together to synchronize the movement of various parts and ensure proper timing and operation of the machinery.

If you're new to the world of timing belts and timing pulleys or considering using them in your machinery, you may have many questions. This comprehensive guide is designed to answer the most frequently asked questions about timing belts and timing pulleys, providing the knowledge and understanding you need to make informed decisions about their use in your projects.

In this guide, we'll cover topics such as how timing belts and pulleys work, common types of belts and pulleys, the advantages and disadvantages of using them, how to select the right belt or pulley for your application, and how to properly maintain and replace them to ensure optimal performance and longevity. By the end of this guide, you'll have a thorough understanding of timing belts and pulleys and be able to incorporate them confidently into your machinery.

What are Timing Belts and Timing Pulleys?

Timing belts and timing pulleys work together to ensure proper engine timing in machines and vehicles that use internal combustion engines.

Timing Belt

A timing belt is a toothed belt that connects the engine's crankshaft to the camshaft(s). The teeth on the belt mesh with the teeth on the timing pulleys attached to the camshaft(s) and the crankshaft. The timing belt controls the opening and closing of the engine's valves, ensuring that the pistons do not collide with the valves and cause serious engine damage.

Timing Pulley

Timing pulleys, also known as sprockets, are typically made of metal and have teeth that mesh with the teeth on the timing belt. They are attached to the camshaft(s) and the crankshaft of the engine and rotate the timing belt along with the engine, ensuring that the belt stays in place and rotates in sync with the engine.

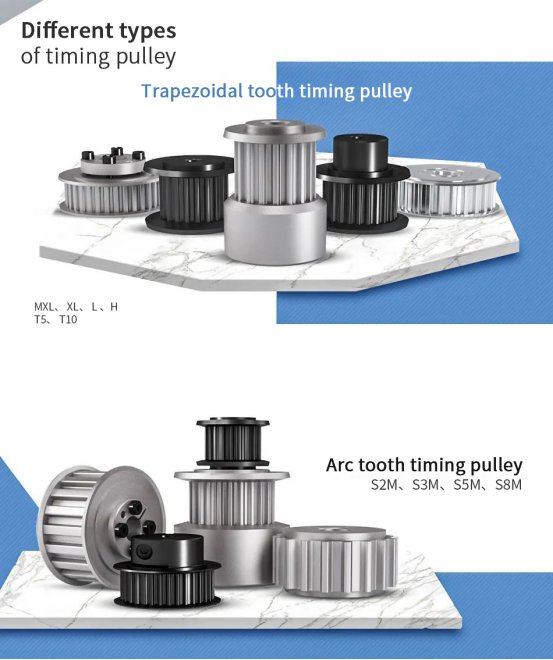

Common timing belts include tming belts, V-belts, and multi-rib belts. tming belts are toothed belts that have teeth that mesh with the teeth on the timing pulleys, while V-belts and multi-rib belts have grooved surface that grips the pulleys. Timing pulleys come in various types and sizes, including standard pitch, metric pitch, and high torque. The size and pitch of the timing pulley must match the timing belt to ensure proper operation.

Overall, timing belts and timing pulleys are essential components in many machines and vehicles that use internal combustion engines, ensuring proper engine timing and preventing damage to the engine.

Advantages of Timing Belt and Timing Pulley

Timing Belt Advantages

The main structure of the timing belt is a ring belt with steel wire rope or glass fiber as the strength layer and covered with polyurethane or chloroprene rubber on the surface. The inner circumference of the tming belt body is made into a tooth shape so that it can be closely meshed with the toothed pulley. The advantages of the timing belt are as follows.

1. The transmission ratio of the tming belt is accurate, there is no sliding effect, and the force on the shaft is small.

2. The structure is compact, with excellent oil resistance, wear resistance and good anti-aging properties.

3. It can maintain good stability in low and high temperature environments, and can withstand temperature fluctuations from -20℃ to +80℃.

4. It has its own buffering and shock absorption capabilities, and the noise generated during operation is very small.

5. The tming belt has high transmission efficiency, and the transmission efficiency can reach up to 98%.

6. The linear speed of the tming belt can reach 50m/s, and the transmission power can reach a few W to hundreds of thousands of W.

7. The tming belt is easy to maintain, does not require lubrication, and the maintenance cost of the equipment is low.

Timing Pulley Advantages

In actual industrial application scenarios, tming pulleys are mainly used in conjunction with tming belts. Some professionals also call tming pulleys, timing wheels or pulleys. As one of the representative components of conveying transmission components, timing pulleys are widely used in many fields such as industrial automation, machine tool equipment, and conveyor.

1. When used in conjunction with timing belts, timing pulleys can buffer the objects being transmitted and are very stable during operation. For some objects that need to avoid collision and shaking during transportation, pulleys plus timing belts are a good choice.

2. As a transmission component, the timing pulley has high precision during the transmission process, and the timing pulley has good clamping and stability during operation, and basically there will be no problems such as cargo falling, loose parts, and jamming gaps.

3. The installation process of the timing pulley is very simple. The timing pulleys for industrial use are generally keyless timing pulleys. When installing, there is no need to drill holes or pull key grooves at the installation point, so the timing pulley is very convenient for installation and subsequent adjustment.

4. The hob that comes with the timing pulley is carefully manufactured by skilled workers according to the precision parameters of the timing belt. It can fit the special structure of the timing belt very well and can also greatly reduce the noise emitted by the timing pulley during operation.

Precautions for Installation and Use of Timing Belts and Timing Pulleys

Timing Belt Install Method

1. When installing the timing belt, if the center distance between the two pulleys can be moved, the center distance of the pulleys must be shortened first, and then the center distance must be reset after the timing belt is installed. If there is a tensioning wheel, loosen the tensioning wheel first, then install the timing belt, and then install the tensioning wheel.

2. When installing the timing belt on the pulley, remember not to use excessive force or pry the timing belt with a screwdriver to prevent the tensile layer in the timing belt from breaking without being noticed from the outside. When designing the pulley, it is best to choose a structure in which the two shafts can move closer to each other. If the structure does not allow it, it is best to install the timing belt and the pulley together on the corresponding shaft.

3. Control the appropriate initial tension. Although there is a small amount of friction transmission between the bottom of the timing belt teeth and the top of the pulley teeth, it mainly relies on meshing to transmit power. Therefore, it does not require a high initial tension like a friction drive belt, and too high tension is harmful to the timing belt: it is easy to cause the bending fatigue of the core wire; it increases the pressure of the pulley tooth top on the belt tooth bottom, shortening the life of the belt; it increases the axial pressure and easily damages the bearing; the harm of too low initial tension: it will make the belt prone to tooth jumping during operation. At the moment of tooth jumping, the belt may break due to excessive tension; the system transmission accuracy deteriorates; the vibration and noise increase.

Precautions during the use of timing belts

1. Reasonable adjustment of load

As a transmission component, the timing belt first needs to have a certain load-bearing capacity, but at the same time this load-bearing capacity is also limited. The maximum tensile force that timing belt products of different specifications can withstand is different. The maximum load capacity of the timing belt must not be ignored in pursuit of transmission efficiency. Therefore, during the use of the timing belt, the weight and quantity of the transported items must be reasonably adjusted according to its maximum load capacity. If the timing belt has been working under overload, it is easy to cause breakage, which will affect the normal progress of the entire production process and even cause safety accidents.

2. Calibrate the installation position

The timing belt is generally installed on the timing belt conveyor to complete the transmission work, and the accuracy of the installation process also needs special attention. When completing the installation or maintenance operation of the timing belt, it is necessary to accurately calibrate its installation position. Only when the timing belt is installed in the correct position can the stability and safety of the timing belt during operation be guaranteed.

3. Select the starting method

There are many starting methods for timing belts. Generally, the most suitable choice is the voltage reduction starting method. The characteristic of the voltage reduction start-up method is that it can start the timing belt conveyor at a relatively slow speed, thereby playing a certain protective role for the timing belt. It can not only reduce the failure rate of the transportation equipment, but also extend the overall service life of the timing belt, thereby achieving the effect of saving repair and maintenance costs. Therefore, from a long-term perspective, it is more reasonable to choose the voltage reduction start-up method.

4. Selection of buffer devices

The timing belt conveyor is usually equipped with a buffer device. The buffer device obviously plays a certain buffering role in the work of the timing belt, and its core component is the buffer spring. Therefore, the selection of the buffer device is actually to select a buffer spring with appropriate elasticity to maximize the protection of the timing belt.

5. Configuration of auxiliary equipment

In actual use, the timing belt is sometimes inevitably partially overloaded. At this time, it is particularly important to configure appropriate auxiliary equipment. The role of the auxiliary equipment is mainly to reduce part of the load of the timing belt when the timing belt is overloaded, and it can also play a certain protective role for the timing belt.

The above-mentioned points of attention in the use of timing belts, if they can be achieved in accordance with the standards in the actual production and transportation process, will be very beneficial to extend the service life of transportation equipment, reduce the failure rate and maintenance cost of timing belts, and improve the transmission efficiency of timing belts. It is more important to use equipment in a reasonable and standardized manner than to purchase and use more expensive equipment.

Timing pulley installation

Timing belt and timing pulleyare used together, and neither of them can be missing. Therefore, when installing the device, the tooth type of the timing pulley should be matched, so that the installation can be completed normally.

1. Cut off the power supply of the machine

2. Confirm whether it is in the same plane

Adjust to make the X dimension 0 (zero) as much as possible. Put the ruler against the side of the pulley to confirm whether the pair of pulleys are in the same plane.

3. Shorten the axis distance

Loosen the bolts of the sliding base, etc., shorten the axis distance, so that the belt can be easily installed on the pulley.

4. Tension the belt

Align the belt teeth with the tooth grooves of the pulley, slowly pull the sliding base, and tighten the belt. Because the belt is slightly shorter when no tension is applied, the pulley with a large number of teeth sometimes does not fully mesh with the belt, so it should be pulled slowly to eliminate the part where the belt and pulley are not meshed properly.

5. Tighten the belt to the specified tension

Tighten the belt and press at the midpoint of the belt span (the part of the belt not touching the pulley) to produce a certain amount of deflection (16/1000 of the span) so that the deflection load at this time is equal to the value calculated according to the following formula.

6. Re-adjust the alignment

With the belt tensioned, check the alignment again with a ruler. If there is any abnormality, remove the belt and readjust it.

Especially when using a single-sided bearing, the shaft may bend during operation and the belt may deviate to the opposite side of the bearing. In this case, the parallelism of the shaft should be corrected in advance to eliminate the deflection.

7. Secure the sliding base to ensure that it does not move.

8. Check the meshing condition

Turn the pulley slowly to check whether the belt and pulley are meshing accurately. If the belt cannot mesh accurately, please check the following items:

①The belt is too tight or too loose.

②The outer diameter of the pulley is abnormal (for example, the outer diameter becomes smaller due to wear, etc.).

③The shape of the pulley does not match the shape of the belt.

Precautions during the use of timing pulleys

1. When selecting the mounting frame for timing pulley, we need to pay attention to the fact that the timing wheels and timing pulleys need to carry out load transmission after installation. Therefore, there are certain requirements for the load performance and mechanical strength of the mounting frame. This is also to ensure that the timing wheels can always keep the axis parallel during operation.

2. When the timing pulley needs to be installed in the timing belt, if the installation is not smooth or stuck, you must not use brute force to force the timing wheel and the timing belt to be clamped. At the same time, it is forbidden to use some sharp objects to pry open the stuck timing belt. These operations will not only fail to complete the installation of the timing wheel and the timing belt, but also cause damage to the timing belt and the timing wheel, and will also bring hidden dangers to subsequent use.

3. When installing the timing pulley, the correct method is to first choose a structure in which the center of the timing wheel can realize flexible adjustment of the spacing. This structure can first reduce the spacing of the timing wheel body to a range that is easy to install in the timing belt, and then increase the spacing to a suitable value after the timing belt is clamped. If the wheel structure of the selected timing wheel cannot be adjusted at will, then the best solution is to install the timing wheel and the timing belt together on the corresponding bearing.

4. During the installation of the timing pulley, it is necessary to pay special attention to ensure that the two axes of the timing wheel are directly parallel. If the axes are not parallel, the timing wheel will deviate, jump teeth and other undesirable phenomena during operation, and will also aggravate the wear inside the timing wheel.

5. After the timing pulley is installed, the tension of the entire timing wheel traditional system needs to be adjusted according to the actual situation.

Tension adjustment of timing pulley transmission system

After a long period of work, the timing wheel transmission system may experience abnormal phenomena such as loose or overly tight timing belts. This will cause the timing belt and the timing wheel to not fit tightly, thus affecting the accuracy and efficiency of the entire traditional system. Therefore, users must regularly test and adjust the tension of the timing wheel transmission system. Once the tightness of the timing belt pulley is found to be abnormal, it needs to be adjusted and resolved immediately. Most timing wheel transmission systems are equipped with special tension adjustment devices, such as automatic tensioning devices, tensioning control wheels, regular tensioning devices, etc., which are more common and convenient to use.

How to Select Timing Belt and Timing Pulley Correctly

Selection of timing belts

1. Width of timing belts

As mentioned above, timing belts are one of the key components used in conjunction with timing wheels. In real life, timing belts are generally called belts. For timing wheels of different specifications, timing belts of appropriate width must be equipped. In actual use, it is necessary to select the corresponding belt width according to the design structure of the timing wheel and the corresponding belt tension table provided by the manufacturer. If the selection is not appropriate, it is easy to cause problems such as timing belt slippage or timing belt breakage during use.

2. Diameter of the center hole of the timing belt

The center hole diameter of the timing wheel is also one of the product parameters that need to be focused on when selecting the timing wheel. Under normal circumstances, the center hole diameter of the timing wheel is determined according to the diameter of the timing belt wheel shaft installed on the transmission equipment. Note that the two must be able to match and use, otherwise the timing wheel cannot be correctly selected.

3. Keyway of the center hole of the timing belt

When selecting the timing wheel product, it is necessary to consider whether there is a keyway in its center hole. This is because the timing pulley is generally connected to the motor and used as the transmission source. Therefore, in order to maximize the power transmission of the motor to the timing wheel, a keyway needs to be set at the center hole of the timing wheel to avoid slippage between the timing wheel and the installation shaft, which affects the transmission.

Of course, in addition to the above factors, there are many other factors that need to be considered in the selection of timing wheels, such as the need for the timing belt to match the tooth shape of the timing wheel, the specific length of the timing belt, etc. For any combined device, it is necessary to be very careful in the selection of each component. If the degree of fit between the components is not optimal, not only can normal installation operations not be performed, but there is also a high probability of failure during use. This is why the product selection of timing wheels should be carefully considered.

Selection of timing pulleys

1. The selection of meshing parameters such as tooth type and pitch of timing pulleys is consistent with the parameters required by timing belts. You only need to determine the required number of teeth or diameter and structure.

2. When determining the number of teeth or diameter of timing pulleys, you need to first determine the number of teeth of the small timing pulley, and then determine the number of teeth of the large timing pulley according to the transmission ratio.

3. In order to ensure the service life of the timing pulley, when selecting a small timing pulley, the diameter needs to be larger than the minimum bending diameter allowed in the timing pulley selection table, and then converted into the minimum number of teeth according to the diameter. Under the premise that the structure and cost allow, considering the life of the timing belt, the number of teeth of the small timing pulley should be slightly more than the minimum number of teeth allowed. After determining the number of teeth of the small timing pulley, the main need is to determine the number of teeth of the large timing pulley according to the transmission ratio. Then determine the center distance between the two pulleys according to the transmission structure, and finally calculate the pitch line length and total number of teeth of the timing belt according to the pitch of the timing belt.

How are Timing Belts and Timing Pulleys Maintained?

Proper maintenance is essential to ensure the reliable operation of timing belts and pulleys. Below are some of the recommended maintenance procedures.

1. Regular Inspections: Timing belts and pulleys should be inspected regularly to detect wear and tear, misalignment, contamination, and tension issues. It should perform inspections according to the manufacturer's guidelines, which usually involve checking the belt and pulleys for wear, damage, or signs of excessive stretching.

2. Cleaning: Dirt, dust, and other debris can accumulate on the timing belt and pulleys, causing damage and reducing performance. Regular cleaning can help prevent these issues. Cleaning should be done using a soft, dry cloth or a brush to remove accumulated debris.

3. Lubrication: Timing belts and pulleys are usually self-lubricating, but some manufacturers recommend the application of lubricant to the pulleys. Using a suitable lubricant that does not degrade the belt material should be applied according to the manufacturer's recommendations.

4. Tension Adjustment: Timing belts must be properly tensioned to ensure proper operation. Over time, the tension can change due to wear, stretching, or other factors. It should check tension regularly and make adjustments as needed, following the manufacturer's recommendations.

5. Replacement: Timing belts and pulleys have a limited lifespan, and they should replace according to the manufacturer's recommendations or when wear or damage is detected during inspection. It should perform replacement with high-quality replacement parts that meet the manufacturer's specifications.

6. Storage: If the timing belt and pulleys are not used for an extended period, they should be stored in a cool, dry place, away from direct sunlight and extreme temperatures. It is also recommended to store them in their original packaging to prevent contamination and damage.

Proper maintenance of timing belts and timing pulleys involves regular inspections, cleaning, lubrication, tension adjustment, and replacement according to the manufacturer's guidelines. Following these procedures can help ensure reliable operation and extend their lifespan.

Common Problems With Timing Belts and Timing Pulleys

While timing belts and timing pulleys offer many advantages, they can also experience various problems affecting their performance and reliability. Some common issues with timing belts and timing pulleys include:

Common Problems in Using Timing Belts

1) What kind of timing belt should be selected when the cleanliness requirement is high?

Polyurethane timing belts are more recommended for working conditions with high cleanliness requirements. This is because polyurethane timing belts have significantly improved dust drop compared to rubber timing belts and have better wear resistance.

2) Does the discoloration of polyurethane timing belts affect the use?

No effect. The reason for the discoloration of polyurethane timing belts is largely due to oxidation discoloration over time, but its own mechanical strength and working performance have not weakened.

3) Why does the timing belt shake during use?

The shaking phenomenon of the timing belt during use is generally due to the long axis spacing and insufficient belt tension, which leads to unstable operation of the timing belt. You only need to readjust the tension of the timing belt pulley to solve this problem.

Common Problems in Using Timing Pulley

1) What is the main application difference between aluminum alloy and S45C timing wheels?

①S45C is a carbon quenched and tempered steel. This material has good wear resistance and stress resistance. The disadvantage is that it is heavy and is mainly used in heavy-load transmission.

②Aluminum alloy materials are light in weight and are more commonly used in light-load timing belt transmission.

2) Can timing wheel products be shipped without riveting flanges?

The answer is yes. Generally speaking, timing wheel products need to be shipped with riveted flanges, but if the customer requires the product to be shipped without riveting flanges, you can flexibly choose not to rivet flanges or only rivet flanges on one side.

3) Can keyless timing wheels be disassembled by loosening the screws?

The keyless timing wheel is locked by the deformation of the expansion sleeve. When disassembling, the expansion sleeve will be tightened due to deformation, which means that it cannot fall out automatically. The solution is that the expansion sleeve is designed with corresponding disassembly screw holes. You only need to use screws to push the expansion sleeve out from the disassembly screw holes.

4) Will the threaded holes of aluminum alloy timing wheels not be locked tightly?

Since aluminum alloy is relatively soft compared to other alloy materials, if the tightening force is too large during the tightening process, the teeth may slip. Therefore, it is recommended that if there is an obstruction during the tightening process, stop tightening immediately, and there will be no problem of being unable to tighten.

5) What are the surface treatments for timing wheels? What is the main function?

The surface treatment methods for aluminum alloy timing wheels are mainly natural anodizing, black anodizing, hard anodizing, and electroless nickel plating. The surface treatment of S45C timing belts mainly includes blackening (iron tetroxide) and electroless nickel plating.

The main function of surface treatment is to improve the wear resistance and corrosion resistance of the timing wheel surface, and of course it also improves the aesthetics of the product to a certain extent.

Conclusion

In summary, timing belts and pulleys are critical components of many machines and vehicles, ensuring accurate and synchronized movement between the engine or motor and other components. Using timing belts and pulleys provides several advantages, such as increased efficiency, reduced noise, and improved reliability. However, common problems can arise with timing belts and pulleys, such as wear and tear, misalignment, and contamination, which can be prevented or addressed through proper maintenance procedures, including regular inspections, cleaning, lubrication, tension adjustment, and replacement. Proper selection of timing belts and timing pulleys is also essential, considering factors such as size, material, tooth profile, tension system, application, and manufacturer. Proper maintenance and selection of timing belts and pulleys are crucial for optimal machine and vehicle performance, ensuring reliable operation and extending lifespan.