ABS Plastic

Characteristics

It has good comprehensive properties, high impact strength, chemical stability, and excellent electrical properties.

It has good weldability with 372 organic glass, and can be made into two-color plastic parts. It can also be chrome-plated and spray-painted on the surface.

There are high-impact, high-temperature-resistant, flame-retardant, reinforced, and transparent grades.

It’s fluidity is slightly worse than that of HIPS, better than that of PMMA, PC, etc., and it has good flexibility.

ABS engineering plastic has excellent comprehensive properties, excellent impact strength, good dimensional stability, electrical properties, wear resistance, chemical resistance, dyeability, and is good for molding and machining. ABS resin is resistant to water, inorganic salts, alkalis, and acids, insoluble in most alcohols and hydrocarbon solvents, but easily soluble in aldehydes, ketones, esters, and some chlorinated hydrocarbons.

The disadvantages of ABS engineering plastic: The heat distortion temperature is relatively low, it is flammable, and the weather resistance is poor.

Applications

It is suitable for making general mechanical parts, wear-resistant and friction-reducing parts, transmission parts, and electrical parts.

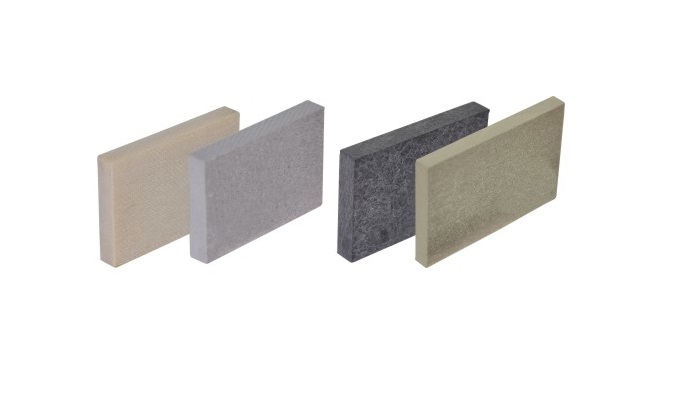

ABS board

ABS+PC

It is commonly known as ABS with polycarbonate, and it is one of the few composite materials that can be widely used in China.

Characteristics

It does not self-ignite. When burned by an external fire, small particles similar to those when polycarbonate burns will precipitate on the surface, and the black color is lower than that of ABS.

Applications

It is commonly found in electrical components, mechanical parts, etc.

PA Polyamide (commonly known as Nylon)

Characteristics

Tough, firm, wear-resistant, and non-toxic.

Disadvantages

It cannot be in contact with acids and alkalis for a long time.

Applications

It is often used to make combs, toothbrushes, coat hangers, fan ribs, net bag ropes, outer packaging bags for fruits, etc.

PC Polycarbonate

Polycarbonate, abbreviated as PC engineering plastic. PC material is actually one of the engineering plastics we mentioned. It is a material widely used around the world.

Characteristics

Polycarbonate is colorless and transparent, heat-resistant, impact-resistant, and flame-retardant. It has good mechanical properties within the normal operating temperature range. Compared with poly(methyl methacrylate) with similar properties, polycarbonate has better impact resistance, higher refractive index, and better processing performance.

Disadvantages

The wear resistance of polycarbonate is poor, and some polycarbonate devices used for easily worn applications need special treatment on the surface.

Applications

Common daily applications include optical discs, eyeglass lenses, water bottles, bulletproof glass, goggles, bank bulletproof glass, headlights, etc., as well as animal cages and pet cages.

Polycarbonate is also used to make the helmet visors of astronauts who have landed on the moon.

PC board

PMMA Poly(methyl methacrylate)

Disadvantages:

The surface hardness of PMMA is not high, it is easy to be scratched, the impact resistance is low, and the molding flow performance is poor, etc.

Super transparent PMMA materials are mainly used for mobile phone protective screens. This product is divided into two types: with a hardening coating and without a hardening coating.

Characteristics:

It has excellent light transmittance, no impurities, a static protective film, and the hardness can reach above 5-6H after the surface is hardened.

Currently, the PMMA material recommended for hardening treatment, which is called "raw board" in China.

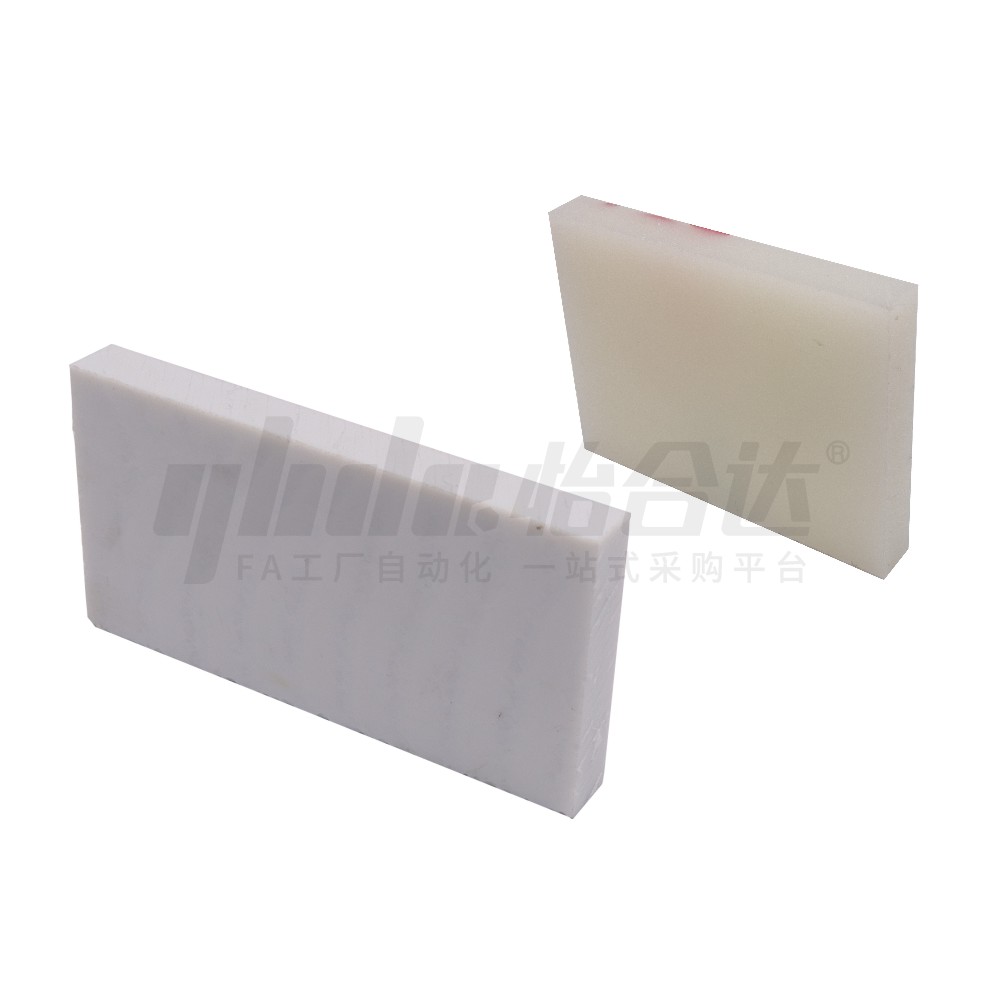

It is a milky white opaque crystalline linear polymer.

Characteristics

It has good comprehensive properties, and its fatigue resistance is the best among thermoplastic plastics. It has excellent mechanical properties at room temperature.

It has good wear resistance, a small friction coefficient, good dimensional stability, a glossy surface, and good creep resistance, twist resistance, repeated impact resistance, and unloading recovery resistance.

Disadvantages

The molding shrinkage rate is large, the thermal stability is poor, it is easy to burn, and it is easy to age when exposed to the sun in the atmosphere.

Applications

It is suitable for making wear-resistant and friction-reducing parts, transmission parts, as well as parts for chemical industry, instruments, etc.

POM board

PP Polypropylene

Characteristics

It is non-toxic, odorless, has a small density, and its strength, stiffness, hardness, and heat resistance are all better than those of low-density polyethylene. It can be used at about 100 degrees Celsius. It has good electrical properties and high-frequency insulation performance, which is not affected by humidity.

Disadvantages

It becomes brittle at low temperatures, is not wear-resistant, and is prone to aging.

Applications

It is suitable for making general mechanical parts, corrosion-resistant parts, and insulating parts.

Common acids, alkalis, and organic solvents hardly have any effect on it, and it can be used for tableware.

PP board

PE Polyethylene

Polyethylene is odorless, non-toxic, and feels like wax. It has excellent low-temperature resistance (the lowest operating temperature can reach -70 to -100 °C), good chemical stability, and can resist the erosion of most acids and alkalis (not resistant to acids with oxidative properties). It is insoluble in general solvents at room temperature, has low water absorption, and excellent electrical insulation performance;

However, polyethylene is very sensitive to environmental stress (chemical and mechanical effects), and its heat aging resistance is poor.

PE has a wide range of applications and is divided into high-density, low-density, and linear PE. The most common daily application is to make various plastic films and plastic sheets.

PPO Polyphenylene Oxide

It is a white granule. It has good comprehensive properties, can be used in 120-degree steam, has good electrical insulation, low water absorption, but has a tendency to stress cracking. Modified polyphenylene oxide can eliminate stress cracking.

It has outstanding electrical insulation and excellent water resistance, and good dimensional stability. Its dielectric properties rank first among plastics. MPPO is a modified material made by blending PPO and HIPS, and the materials on the market are all of this type.

It has high heat resistance, with a glass transition temperature of 211 degrees, a melting point of 268 degrees, and a decomposition tendency when heated to 330 degrees. The higher the content of PPO, the better its heat resistance, and the heat distortion temperature can reach 190 degrees.

It has good flame retardancy and self-extinguishing properties. When mixed with HIPS, it has moderate flammability. It is lightweight and non-toxic.

Disadvantages

Its fluidity is poor, it is similar to a Newtonian fluid, and the viscosity is relatively sensitive to temperature. The thickness of the product is generally above 0.8 mm. It is extremely easy to decompose, and corrosive gases are generated during decomposition.

Applications

It is suitable for making heat-resistant parts, insulating parts, wear-resistant and friction-reducing parts, transmission parts, medical and electronic parts.

It can be used as parts such as gears, fan blades, valves, etc. used at higher temperatures, and can replace stainless steel.

It can be used to make screws, fasteners, and connectors.

Electrical parts of motors, rotors, casings, and transformers.

PVC Polyvinyl Chloride

Its original color is slightly yellowish and translucent with a luster. Its transparency is better than that of polyethylene and polypropylene, but worse than that of polystyrene. Depending on the amount of additives used, it is divided into soft and hard polyvinyl chloride. The soft products are soft and tough, with a sticky feel. The hardness of the hard products is higher than that of low-density polyethylene but lower than that of polypropylene, and a whitening phenomenon will occur at the bent places.

Common products: plates, pipes, soles of shoes, toys, doors and windows, wire sheaths, stationery, etc.

PVC board

TPE Thermoplastic Elastomer

The transparent series has various softness and hardness levels and can be directly processed by injection molding. Its transparent appearance, smooth surface, soft touch, and non-toxic characteristics make it an excellent transparent material.

It is suitable for various transparent components, such as toys, soft insoles, and general transparent products, etc.

TPO Thermoplastic Polyolefin Elastomer

It is usually a copolymer of ethylene and octene, etc.

Thermoplastic polyolefin elastomer is a high-performance elastic material. Its properties are similar to those of rubber, and its processing method is the same as that of plastic. It is a replacement product for rubber and is applied in fields such as cars, cables, light textiles, construction, and home appliances.