Process Steps:

Confirm the usage method of the cable carrier - Confirm the function of the cable carrier - Determine the type and series of the cable carrier through the above two steps - Confirm the specification and size of the cable carrier according to the size, quantity, and stroke of the cables - Select the opening direction of the cable carrier - Finally, determine the model of the cable carrier.

1. Confirm the Usage Method

Common usage methods of cable carriers include: horizontal overhead, vertical standing, vertical hanging, lateral inversion, rotation, and sliding.

Horizontal Overhead, Vertical Standing, Vertical Hanging, Lateral Inversion Usage: Except for 3D cable carriers (VAR series) and corrugated cable carriers (VAK series), other cable carriers can meet the usage requirements. However, when used vertically standing, the joint movement method needs to be considered.

Horizontal Overhead

Vertical Standing

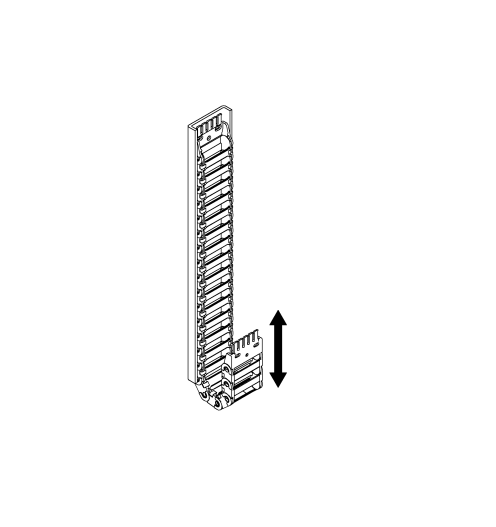

Vertical Hanging

Lateral Inversion

Rotation Usage: Cable carriers for rotation usage need to be able to bend bidirectionally. The VAS series cable carriers can meet the corresponding requirements.

Rotation

Sliding Usage: For long strokes (more than 10 meters), it is recommended to use sliding cable carriers. The VAJ series cable carriers can be used for sliding.

Sliding

2. Confirm the Function of the Cable Carrier

Conventional Working Conditions: It is recommended to use domestic cable carriers, such as VBY series, VBC series, VBD series, VBF series, VBP series, VBQ series, VBR series, VBS series, VBT series, VBU series.

High - Speed and High - Acceleration: It is recommended to use imported cable carriers or domestic silent cable carriers, such as VAX11 series, VAC series, VAD series, VAE series, VAF series, VAH series, VAJ series, VAK series, VAQ series, VAW series, VBK series, VBF11 series.

Cleanroom Applications:

① ISO Class1: VAQ series, VAK series.

② ISO Class3: VAX11 series, VAJ series, VAC series.

Silent: VBK series, VBF11 series, VAX11 series, VAQ series, VAK series.

Anti - static: VAX01 series.

Robot Usage: VAR series.

3. Confirm the Cable Carrier Size

During the selection phase, it is usually necessary to confirm the inner height, inner width, bending radius, and length of the cable carrier.

Inner Height and Inner Width: Select the inner height and inner width according to the cable layout. A gap needs to be set between pipelines, and the filling inside the cable carrier should not exceed 80%. The minimum gaps required for various pipelines are as follows:

① The minimum gap for round cables is 10% of the outer diameter.

② The minimum gap for hydraulic pipes is 20% of the outer diameter.

③ The minimum gap for air pipes is 5 - 10% of the outer diameter.

④ The minimum gap for flat cables is 10% of both the width and the thickness.

Bending Radius: It depends on the hardest or thickest pipe or wire placed inside the cable carrier and should meet the recommended values of the wire and pipe manufacturers. The bending radius of the cable carrier should be greater than the minimum bending radius of the wire and pipe.

The reference values of the minimum bending radii allowed for different wires and pipes are as follows:

① For round cables: 8 - 10 times the outer diameter.

② For optical cables: 10 - 15 times the outer diameter.

③ For air pipes: 10 - 12 times the outer diameter.

④ For hydraulic pipes: 10 - 15 times the outer diameter.

Length: Calculate the length of the cable carrier according to the stroke. The calculation formula is as follows:

LK = S + K + ΔM 2

Note: LK is the length of the cable carrier, S is the stroke of the cable carrier, K is the bending radius allowance, and ΔM is the offset between the fixed - end joint and the middle of the stroke.

According to the calculated length of the cable carrier and the pitch of the selected cable carrier, the number of chain links N of the cable carrier can be calculated by using the formula length÷pitch = number of chain links (rounded up).

4. Select the Opening Direction of the Cable Carrier

According to different structures, cable carriers are divided into inner diameter opening, outer diameter opening, and inner and outer diameter opening. You can select the corresponding installation direction according to the principle of easy installation.

5. Confirm the Cable Carrier Model

After completing the above steps, the type and size of the required cable carrier can be determined. According to the model composition rules of the selected code, the model of the cable carrier can be determined.

Contact Us

After you have determined the required cable carrier model, in order to provide you with a more comprehensive and professional service, you can contact the sales manager of our company. Our sales managers have rich experience and professional knowledge in cable carrier products. Whether it is product selection optimization, technical parameter consultation, or discussion of the overall solution for project applications, they can provide you with accurate and effective suggestions based on their profound industry insights.